Renewable Diesel

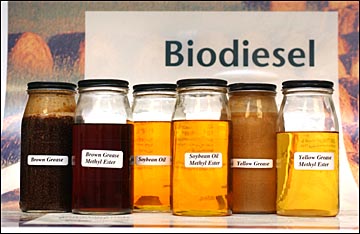

Biodiesel can be made from soybean oil (middle two jars), but it also can be made from from brown grease (left two jars) or yellow grease (right two jars). Brown grease can come from a rendering plant or a sewer trap. Yellow grease also can come from a rendering plant or from restaurants.

Renewable diesel is made from a variety of fats including animal fats, used cooking oils and distiller corn oils. Its composition has no alcohol and no oxygen, but is a true hydrocarbon, having the same properties and structure as petroleum diesel. As such, fuel refiners can drop renewable diesel into diesel fuel at any percentage and distribute it through the existing diesel pipeline and infrastructure. In fact, renewable diesel is so close to the real deal that companies can operate diesel-equipped vehicles and machinery entirely on renewable diesel, with no performance loss and without the environmental impact.

Renewable diesel is also known as hydrotreated vegetable oil (HVO) because of its common source. Since it derives from natural, organic products, HVO is 100% renewable. The world has an infinite supply of renewable diesel because it is made from products that are constantly being re-grown from the Earth’s soil. Whereas crude oil requires digging and drilling in select regions, vegetable oil comes from products that are harvested throughout the world on a seasonal basis. Simply put, the world might have a finite supply of crude oil, but there will always be vegetables as long as water-based life exists on this planet.

Renewable diesel can be made by one of three different processes: hydrotreating, thermal conversion, and biomass-to-liquid. Each process radically alters the original composition and chemical makeup of the raw material:

- Hydrotreating: Alternately known as hydrogenation, this method utilizes triglycerides, which add hydrogen to raw materials to eliminate elements of oxygen, nitrogen, and metal. Once the oil has undergone this process, it will burn cleaner as renewable diesel.

- Thermal conversion: Alternately known as depolymerization, thermal conversion creates oil out of carbonized biomass. Once the oil is derived, refinement processes are employed to render the oil appropriate for fuel purposes.

- Biomass-to-liquid: This process involves gasification, which is employed at high temperatures to convert biomass into synthetic, hydrogen-rich gas mixtures.

The benefits of renewable diesel are numerous since it works in all climates and requires no engine modifications. Renewable diesel can be used in all types of automobiles throughout the four seasons of the year, even in subzero temperatures. Vehicles that use renewable diesel can reduce their greenhouse gas emissions by up to 80%, thanks to the fuel’s highly efficient combustion and high cetane number, which is somewhere in the range of 75 to 85.

Renewable diesel is compatible with North America’s preexisting infrastructure for fuel distribution and can therefore be adopted by fuel services throughout the U.S. and Canada in place of conventional fuel types. The fuel can be stored in the same storage tanks previously used to house petroleum fuel. While renewable diesel works best when added directly to an engine, the fuel can also be mixed with biodiesel and fossil diesel.

Biofuels

About Biofuels

Advanced biofuels are fuels produced from biomass sources through a variety of biological, thermal, and chemical processes. These products are similar to petroleum gasoline, diesel, or jet fuel in chemical makeup and are therefore considered infrastructure-compatible fuels. These fuels can be used in vehicles without requiring engine modifications and can use existing petroleum fuel pipelines and retail distribution systems.

Also called second-generation biofuels, they can overcome the limitations of both fossil fuels and first-generation predecessors by utilizing existing infrastructure, reducing emissions, and better utilization of our land when coupled with proper sustainability certification.

Advanced biofuels are considered “low carbon fuels” based on their total impact on the environment and economy. These fuels can provide significant environmental and social benefits if developed with caution and foresight. The best biofuels are those that make it environmentally and economically possible to produce more food and fuel in a way that reduces emissions, conserves soil and water resources, protects forests and native ecosystems, and improves the economic welfare of farmers, workers, and communities.

Life-cycle accounting allows biofuels to be rated based on all the greenhouse gas emissions produced from creation or extraction to the use in a vehicle, including supply chain emissions. Most regions throughout the world rate fuel greenhouse gas emissions based on this scoring approach.

Land use is an important part of biofuel production, as feedstocks are frequently sourced from biomass. The inclusion of land use change impacts help to minimize the use of biomass that compete with food production.

A Growing Market

Biofuels are currently mandated in 62 countries around the world, and agriculture is delivering the feedstock to make those biofuels. The demand for clean diesel and jet fuels is the most rapidly growing segment of the renewable fuels market, as commercial transportation like the aviation industry carry more people than ever before and have committed to lower their carbon footprint.