Introduction

Lithium grease is a versatile and essential lubricant used in a wide range of industrial, automotive, and household applications. Its unique chemical composition provides exceptional stability, protection, and performance under various conditions. Understanding the benefits, applications, and proper usage of lithium grease can help in maintaining machinery and extending the lifespan of components. This article delves into the properties of lithium grease, its advantages, different types available, and the best practices for its application.

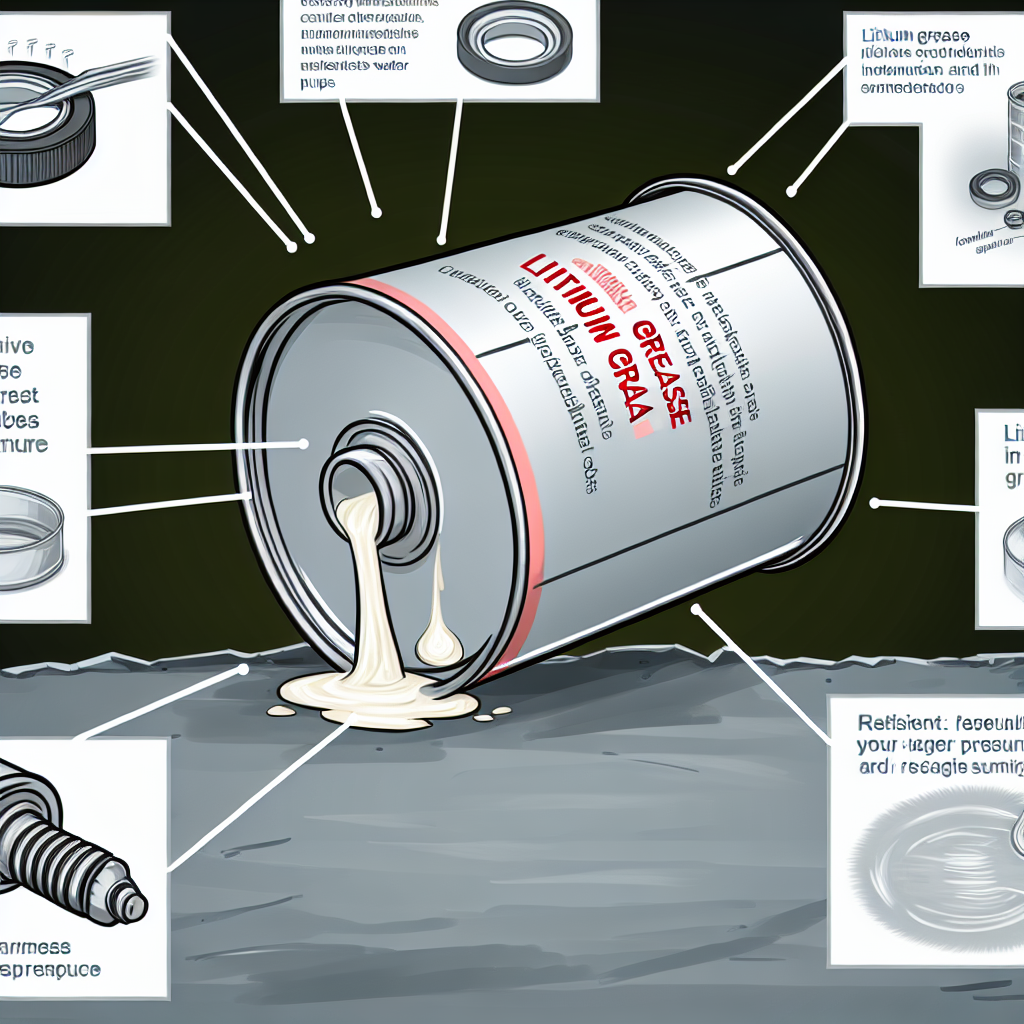

What is Lithium Grease

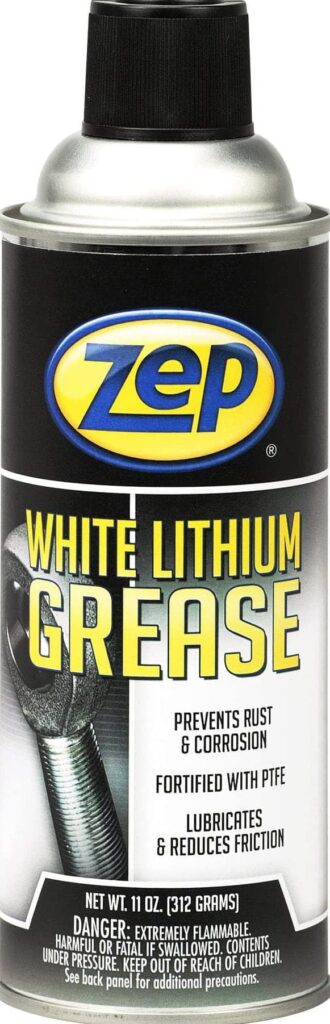

Lithium grease is a lubricant made by combining lithium soap with base oils and, often, performance additives. It is known for its high melting point, excellent water resistance, and the ability to provide long-lasting lubrication. The thick consistency of lithium grease makes it ideal for applications where it needs to adhere to surfaces without dripping or running off, even under high-temperature conditions. These properties make lithium grease a go-to choice for many industries, from automotive to heavy machinery and consumer products.

Advantages of Lithium Grease

The popularity of lithium grease is largely due to its myriad advantages. Firstly, its chemical stability allows it to perform well in a variety of temperatures and environmental conditions. This makes it suitable for both high-heat and cold environments, ensuring that components remain protected regardless of the setting. Secondly, lithium grease has exceptional water resistance, preventing the ingress of water that could lead to corrosion and wear.

Moreover, lithium grease forms a protective barrier that reduces friction and wear between moving parts. This not only ensures the smooth operation of machinery but also extends the lifespan of components, reducing the need for frequent replacements and repairs. Additionally, lithium grease has excellent adhesion properties, making it stick to surfaces effectively without being displaced by motion or external elements. This strong adhesion ensures consistent lubrication over time.

Types of Lithium Grease

There are several types of lithium grease, each formulated to meet specific requirements and applications. The most common type is general-purpose lithium grease, which is designed for a broad range of uses, including automotive and household applications. It is suitable for lubricating bearings, hinges, and other moving parts.

High-temperature lithium grease is formulated with additional additives to enhance its performance under extreme heat conditions. This type of grease is ideal for applications where components are exposed to high operating temperatures, such as in automotive engines and industrial machinery.

Another variant is lithium complex grease, which has an even higher melting point and enhanced chemical stability. This makes it suitable for heavy-duty applications that require superior performance under extreme conditions. Lithium complex grease is often used in heavy machinery, marine applications, and other demanding environments.

Applications of Lithium Grease

Lithium grease is used in a wide variety of applications due to its versatile nature. In the automotive industry, it is commonly used to lubricate wheel bearings, chassis components, and other moving parts. Its ability to withstand high temperatures and resist water makes it an ideal choice for these applications.

In industrial settings, lithium grease is used to lubricate machinery, conveyor belts, and other equipment. Its stability and durability ensure that machinery operates smoothly, reducing downtime and maintenance costs. It is also used in the marine industry to protect components from the corrosive effects of saltwater.

Household applications of lithium grease include lubricating door hinges, garage door tracks, and lawn equipment. Its long-lasting lubrication properties make it a convenient choice for household maintenance tasks, ensuring that moving parts remain functional and do not wear out prematurely.

Best Practices for Using Lithium Grease

To maximize the benefits of lithium grease, it is important to follow best practices for its application. Firstly, ensure that the surfaces to be lubricated are clean and free of dirt, debris, and old grease. This can be achieved by wiping the surfaces with a clean cloth and using a suitable solvent if necessary.

Next, apply the lithium grease evenly, ensuring that all moving parts are adequately lubricated. Use a grease gun for precise application, especially in tight or hard-to-reach areas. Avoid over-application, as excess grease can attract dirt and debris, leading to increased wear and tear.

Regular maintenance is also crucial. Periodically check the condition of the lubricated components and reapply lithium grease as needed. This ensures continuous protection and optimal performance of the components. In high-temperature or high-stress applications, more frequent reapplication may be necessary to maintain adequate lubrication.

Environmental and Safety Considerations

When using lithium grease, it is important to consider environmental and safety factors. Proper disposal of used grease is crucial to prevent environmental contamination. Follow local regulations for the disposal of used lubricants, and avoid allowing grease to enter water sources or soil.

Additionally, while lithium grease is generally safe to handle, it is recommended to use protective gloves and avoid prolonged skin contact. In case of accidental ingestion or contact with eyes, seek medical attention immediately. Always store lithium grease in a cool, dry place, away from direct sunlight and heat sources to maintain its quality.

Conclusion

In summary, lithium grease is a highly effective and versatile lubricant with a wide range of applications across various industries. Its chemical stability, water resistance, and strong adhesion properties make it an invaluable tool in maintaining machinery and components. By understanding the different types of lithium grease and following best practices for its application, users can ensure optimal performance, reduce maintenance costs, and extend the lifespan of their equipment.

Whether for automotive, industrial, or household use, lithium grease remains a reliable solution for lubrication needs. By considering environmental and safety factors, users can also contribute to sustainable practices while benefiting from the exceptional properties of lithium grease.