Introduction

In the realm of industrial and mechanical applications, the need for reliable and durable lubrication cannot be overstated. High temperature lithium grease is a specialized lubricating material designed to function effectively under extreme thermal conditions. This type of grease has particular properties that make it highly valuable in operations where elevated temperatures are a constant challenge. In this comprehensive article, we will explore the essential aspects of high temperature lithium grease, including its composition, benefits, applications, and proper usage.

Composition of High Temperature Lithium Grease

At its core, high temperature lithium grease is composed of a thickening agent and base oil, combined with additives to enhance performance characteristics. The thickener is typically a lithium soap, such as lithium stearate, which is known for its excellent thermal stability and water resistance. The base oil can be mineral-based or synthetic, with synthetic options often offering superior high-temperature performance.

To further enhance its properties, this type of grease is fortified with various additives. These may include anti-oxidants to prevent chemical breakdown at high temperatures, anti-wear agents to reduce surface degradation, and corrosion inhibitors to protect metal surfaces from rust and corrosion. The resultant product is a high performance, multi-purpose grease capable of withstanding extreme conditions.

Benefits of High Temperature Lithium Grease

The primary advantage of high temperature lithium grease is its ability to maintain viscosity and performance under severe thermal conditions. This makes it an ideal choice for applications involving prolonged exposure to high temperatures. In addition, its excellent thermal stability minimizes the risk of grease liquefaction or hardening, ensuring consistent lubrication and protection.

Furthermore, high temperature lithium grease offers superior resistance to water and chemicals. This is particularly valuable in environments where equipment may be exposed to moisture or harsh substances. The grease’s water-resistant qualities prevent washout and help maintain an effective lubrication film on metal surfaces.

Another key benefit is its ability to provide long-lasting lubrication, thereby reducing the frequency of maintenance and greasing intervals. This leads to improved operational efficiency and reduced downtime, which are crucial factors in any industrial setting.

Applications of High Temperature Lithium Grease

High temperature lithium grease is used in a wide range of applications across various industries. Primarily, it is employed in environments where machinery and equipment operate under elevated temperatures. Some of the key applications include:

1. Automotive Industry: In automotive applications, this grease is used in wheel bearings, chassis, and other components that are subjected to high friction and heat. Its ability to withstand temperature extremes ensures optimal performance and longevity of critical automotive parts.

2. Manufacturing and Heavy Industry: In manufacturing plants and heavy industries, high temperature lithium grease is utilized in the lubrication of conveyor belts, electric motors, pumps, and bearings. These components often experience intense heat due to continuous operation, making high temperature grease essential for reliable performance.

3. Aerospace and Aviation: Airplane engines and other aerospace components are subjected to extreme temperature variations during operation. High temperature lithium grease provides the necessary lubrication to maintain efficiency and safety standards in these demanding conditions.

4. Steel Mills and Foundries: Equipment used in steel mills and foundries faces some of the most challenging thermal environments. High temperature lithium grease helps protect bearings, gears, and other components, thereby ensuring seamless operation even under intense heat.

Proper Usage and Handling

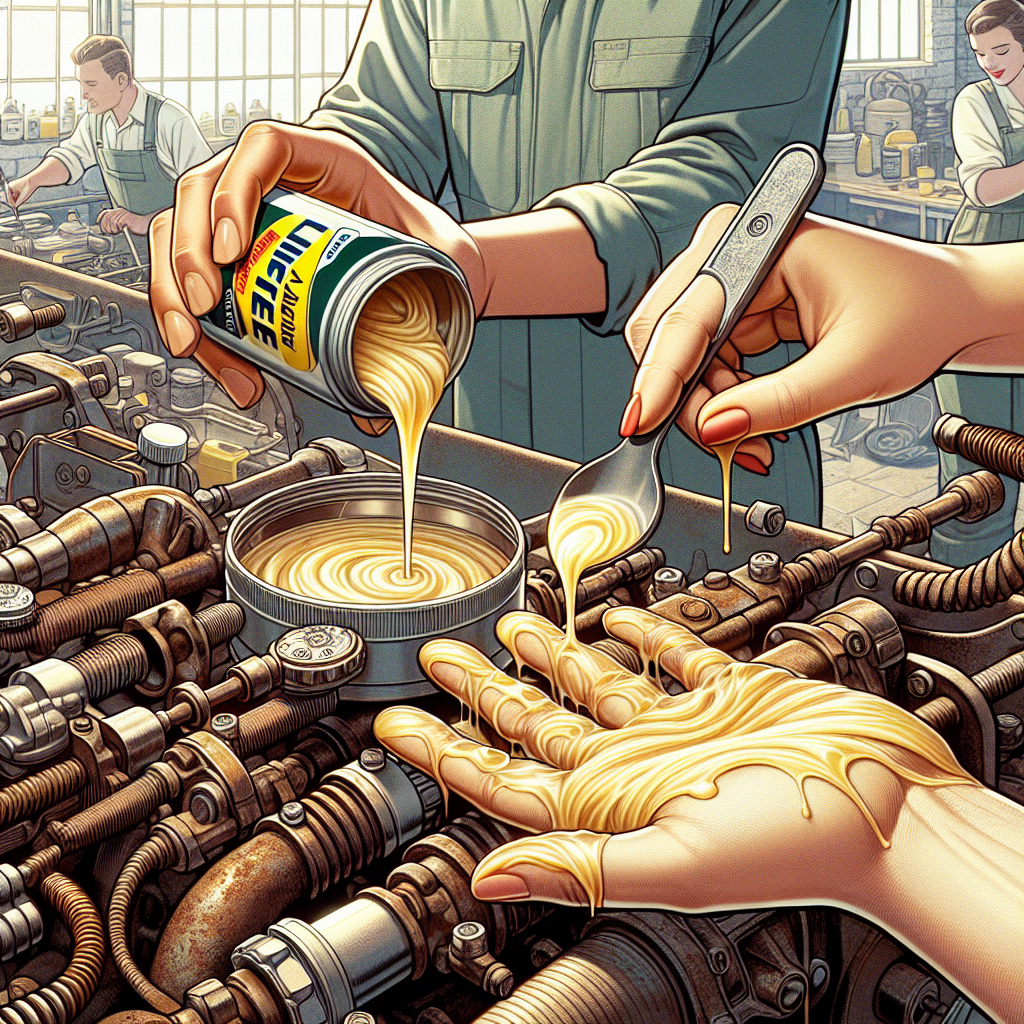

Effective application and handling of high temperature lithium grease are essential to maximize its benefits. It is crucial to ensure the surfaces being lubricated are clean and free of contaminants before applying the grease. This can be achieved through proper cleaning and decontamination processes.

The quantity of grease applied should be sufficient to cover the lubrication surfaces without overburdening the components. Over-greasing can lead to excessive heat buildup and reduced efficiency. It is advisable to follow the manufacturer’s recommendations for specific applications to determine the appropriate amount.

Storage of high temperature lithium grease should also be considered carefully. The grease should be stored in a cool, dry place away from direct sunlight and sources of contamination. Properly sealed containers help prevent moisture and debris from impacting the quality of the grease over time.

Conclusion

High temperature lithium grease plays a pivotal role in ensuring the smooth operation of machinery and equipment exposed to extreme thermal conditions. Its unique composition and superior performance characteristics make it indispensable in various industrial sectors. By providing reliable lubrication, resisting water and chemical exposure, and reducing maintenance intervals, high temperature lithium grease contributes to optimizing operational efficiency and equipment longevity.

Understanding the benefits and appropriate use of this specialized grease allows industries to leverage its full potential. As technology and industrial applications continue to evolve, high temperature lithium grease remains a critical component in the maintenance and operation of high-performance machinery. Properly managed, it can significantly contribute to the success and reliability of various industrial processes.