Introduction

Lithium grease is a versatile and widely-used lubricant praised for its effectiveness in reducing friction, preventing wear and tear, and protecting various mechanical components from corrosion. Recognized for its impressive properties, this grease finds broad applications in industries ranging from automotive to agriculture. This article delves into the characteristics, benefits, and proper use of lithium grease, providing a comprehensive understanding of why it stands out among other lubricants.

What is Lithium Grease

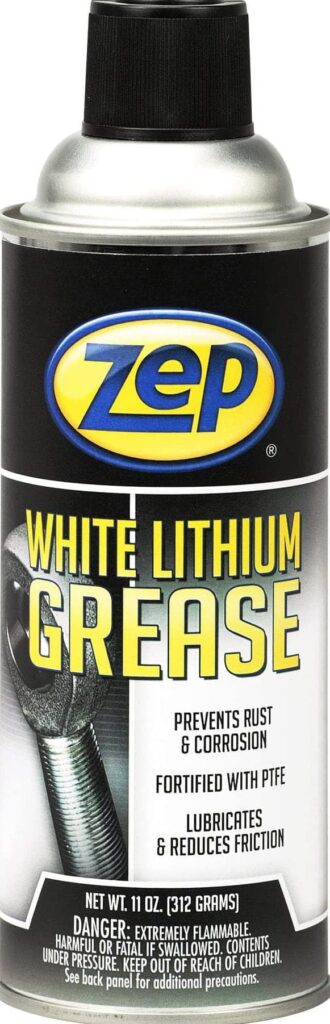

Lithium grease, a type of lubricating grease, is created by combining lithium soap—frequently a mixture of lithium hydroxide and fatty acids—with mineral or synthetic oil. The resulting product is a thick, stable substance that adheres well to surfaces and remains effective across a broad temperature range. Commonly referred to as white lithium grease due to its color, it boasts a smooth consistency and excellent lubricating properties, which make it ideal for various mechanical applications.

Properties of Lithium Grease

To fully appreciate the value of lithium grease, it’s important to understand its key properties. First and foremost, lithium grease provides exceptional stability. It retains its consistency and lubricating abilities even when subjected to significant temperature fluctuations, which is crucial for ensuring reliable performance in different environments.

Furthermore, lithium grease possesses excellent water resistance. This attribute makes it invaluable for applications exposed to moisture or high humidity, as it remains effective and does not wash away easily. Additionally, the grease offers impressive oxidation stability, meaning it resists breakdown over time and maintains its efficiency for extended periods.

Moreover, lithium grease is renowned for its sheer strength and adherence. Once applied, it forms a protective barrier that remains in place, ensuring sustained lubrication and reducing the need for frequent reapplication. These combined properties of stability, water resistance, oxidation stability, and adherence make lithium grease a superior choice for many applications.

Applications of Lithium Grease

The versatility of lithium grease means it can be used in a wide range of applications. In the automotive industry, it plays a critical role in lubricating parts such as ball joints, hinges, bearings, and gears. Its ability to withstand high pressures and intense heat makes it indispensable for maintaining optimal performance and longevity of vehicle components.

Similarly, lithium grease is widely used in the industrial sector. Machines and equipment in manufacturing plants benefit from its application on moving parts, protecting them from wear and tear and ensuring smooth operation. This is particularly relevant in environments where machinery is subject to constant use and high stress levels.

Beyond vehicles and industrial machinery, lithium grease is also employed in agricultural equipment. Tractors, plows, harvesters, and other farming tools experience heavy use and exposure to dirt and moisture. The robust protective qualities of lithium grease help safeguard these tools, contributing to reduced maintenance costs and prolonged equipment life.

Benefits of Using Lithium Grease

The decision to use lithium grease brings with it numerous advantages, starting with its ability to reduce friction and wear. This is essential for maintaining the efficiency and longevity of various mechanical components. By minimizing metal-on-metal contact, lithium grease helps prevent excessive wear, which in turn reduces the likelihood of component failure and costly repairs.

Another significant benefit is its anti-corrosive properties. By forming a barrier against moisture and other corrosive elements, lithium grease effectively protects surfaces from rust and other forms of corrosion. This is particularly important in applications where equipment is exposed to harsh conditions, such as in the automotive or marine industries.

Additionally, lithium grease provides cost-effective maintenance. Its durability and long-lasting nature mean that less frequent reapplication is required, translating to lower maintenance costs over time. The combination of reduced wear, corrosion protection, and extended lubrication intervals results in overall cost savings.

How to Apply Lithium Grease

Proper application of lithium grease is key to maximizing its benefits. Before applying the grease, it’s best to clean the surface or component to remove any dirt, old lubricant, or debris. This ensures that the grease adheres properly and functions as intended.

When using lithium grease, apply it sparingly. A thin layer is often sufficient to provide the necessary lubrication without causing buildup. Excess grease can attract dirt and contaminants, potentially leading to more harm than good. It’s also advisable to use clean tools or gloves when applying the grease to avoid contamination.

After application, periodically check the component or surface to ensure that the grease is still present and performing effectively. Reapplication may be needed based on the operating conditions and frequency of use. Regular maintenance checks help identify when additional lubrication is required.

Comparing Lithium Grease to Other Lubricants

While lithium grease is highly versatile, it’s not the only lubricant available. Understanding how it compares to other types helps in making informed decisions about which to use. For instance, silicone grease is another popular option known for its water resistance and dielectric properties. However, it doesn’t offer the same high-pressure resistance as lithium grease, making it less suitable for heavy-duty applications.

On the other hand, molybdenum disulfide (moly) grease excels in high-load applications due to its superior pressure resistance. Yet, unlike lithium grease, it has a darker color and can stain surfaces, making it less desirable for certain aesthetic or environmental conditions. Each type of grease has its own unique set of properties tailored for specific uses, but lithium grease provides an excellent balance of features suitable for a wide array of general and specialized applications.

Conclusion

In summary, lithium grease stands out as a highly effective lubricating solution, valued for its stability, water resistance, oxidation stability, and adhesive properties. Its diverse applications in the automotive, industrial, and agricultural sectors underscore its importance as a go-to lubricant for reducing wear and tear, preventing corrosion, and ensuring smooth operation of mechanical components. By understanding its properties and proper application techniques, users can fully leverage the numerous benefits lithium grease has to offer, making it a staple in both professional settings and everyday maintenance tasks.