Introduction to High Temperature Aerospace Grease

In the demanding world of aerospace engineering, where reliability and efficiency often spell the difference between life and death, the need for high-quality lubricants cannot be overstated. High temperature aerospace grease stands out as a crucial component in the maintenance and operation of aircraft and spacecraft. This specialized lubricant is designed to withstand extreme temperatures and environmental conditions, ensuring the seamless functioning of intricate mechanical systems. In this article, we will delve into the fundamentals of high temperature aerospace grease, exploring its properties, applications, and the advantages it brings to the aerospace industry.

Understanding High Temperature Aerospace Grease

High temperature aerospace grease is a specially formulated lubricant crafted to endure the intense thermal stresses encountered in aerospace applications. Unlike conventional lubricants, which may break down or lose efficacy at high temperatures, aerospace grease is designed to maintain stability, reduce friction, and protect components from wear and corrosion. This capability becomes increasingly vital as aerospace components often operate within a temperature range of -73°C to 177°C (-100°F to 350°F), with some applications reaching even higher thresholds.

The formulation of high temperature aerospace grease typically involves a synergistic blend of base oils, thickeners, and performance-enhancing additives. Synthetic base oils, such as polyalphaolefins (PAO) or esters, are commonly used due to their superior thermal stability and oxidation resistance compared to mineral oils. Thickeners, including complex soaps or non-soap-based systems like polyurea, provide the required consistency and ensure the grease remains in place during operation. Additives play a crucial role in enhancing properties such as anti-wear, extreme pressure, and corrosion resistance, making the grease suitable for the challenging aerospace environment.

Applications of High Temperature Aerospace Grease

The versatility of high temperature aerospace grease allows it to be used in a wide range of applications throughout various aircraft and spacecraft systems. One of the most common uses is in the lubrication of engine components. Jet engines, for instance, operate at extremely high temperatures and rotational speeds, demanding a lubricant that can effectively reduce friction and prevent component degradation. High temperature aerospace grease is also employed in the lubrication of bearings, actuators, gear mechanisms, and other moving parts that experience high thermal and mechanical stresses.

Beyond engine applications, high temperature grease plays a critical role in other subsystems as well. For example, it is used in the lubrication of landing gear assemblies, where the grease must withstand not only high temperatures but also the impacts and loads experienced during takeoff and landing. In avionic systems, aerospace grease ensures the reliable operation of sensors, switches, and other electronic components that may be subjected to temperature fluctuations and environmental contaminants. Moreover, in spacecraft, these greases are essential for ensuring the long-duration reliability of components in both manned and unmanned missions, where maintenance opportunities are minimal or non-existent.

The Advantages of High Temperature Aerospace Grease

The use of high temperature aerospace grease offers several significant benefits, crucial for both the safety and performance of aerospace vehicles. Firstly, its ability to maintain stability and efficacy at elevated temperatures directly translates into enhanced reliability and longevity of lubricated components. This characteristic minimizes the risk of mechanical failures, which not only improves safety but also reduces maintenance costs and downtime.

Moreover, high temperature grease is designed to provide exceptional protection against wear and corrosion. By forming a robust lubricating film, it guards against material degradation due to friction and oxidation. This is particularly important in aerospace applications where components are often made of lightweight, high-strength materials that can be susceptible to wear if not properly lubricated.

Another key advantage is the enhanced performance under extreme pressure and load conditions. Aerospace components frequently operate under high stress, and a lubricant that can withstand these pressures without breaking down ensures optimal performance and prevents costly damage. Additionally, the specialized additives in high temperature aerospace grease further enhance its resistance to chemical attack from fuels, hydraulic fluids, and other harsh substances commonly found in aerospace environments.

Choosing the Right High Temperature Aerospace Grease

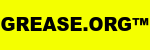

Selecting the appropriate high temperature aerospace grease requires consideration of various factors, including the operating temperature range, load conditions, environmental exposure, and compatibility with other materials in the system. It is essential to consult manufacturer specifications and guidelines to ensure the chosen grease meets the specific requirements of the application.

Furthermore, regular monitoring and maintenance are crucial for ensuring the continued effectiveness of the grease. Periodic inspections, testing, and re-lubrication as necessary can help detect and address potential issues before they lead to significant problems. Aerospace maintenance professionals rely on a comprehensive understanding of lubrication principles and practices to keep aircraft and spacecraft operating safely and efficiently.

Conclusion

In conclusion, high temperature aerospace grease is an indispensable element in the aerospace industry, providing critical lubrication and protection to components operating under extreme conditions. Its unique formulation and performance characteristics make it ideally suited for the rigorous demands of aerospace applications, from engine components to landing gear and avionic systems. By choosing the right high temperature grease and maintaining rigorous lubrication practices, the aerospace industry can ensure the reliability, safety, and performance of its vehicles, ultimately fostering advancements in aviation and space exploration.

As the aerospace industry continues to evolve and push the boundaries of technology, high temperature aerospace grease will remain a vital contributor to its ongoing success, enabling new heights of achievement and discovery.